As Sustainability Project Manager at Siemens in Zürich, the Swedish engineer translates the complex language of circularity into something deeply human: responsibility. With a degree from KTH Royal Institute of Technology, she shapes the future of sustainable industry from within. Her work is guided by one belief – that beauty lies in systems where nothing is wasted and everything finds its way back into the circle of life.

Ladies Drive: Emelie, before we dive into details, could you please explain to us – in a nutshell – what circularity really means?

Emelie Emanuelsson: I think the best way to explain it is through the “R-models”. They span from reduce, reuse, repair, refurbish, to remanufacture, and finally, recycle. If you own a product, you first try to reuse it. If that’s not possible, you repair or refurbish it – and only at the very end do you recycle. Many people still think circularity is all about recycling, but it’s not. It’s really about using the R-models to give everything a second life.

How do you bring this knowledge into a large corporation like Siemens? Can you share a little bit about what you are currently working on?

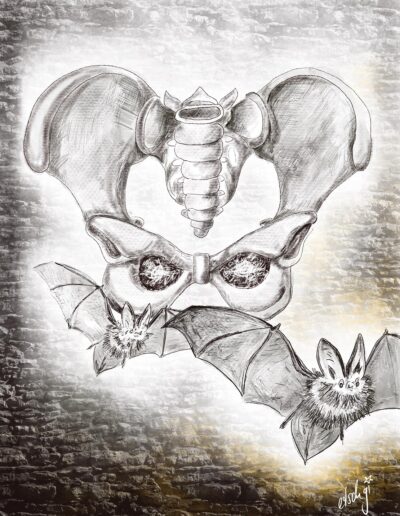

One key aspect is creating circular products. When we design something new, we already need to consider which of the R-strategies will apply at the end of its life. If a product is meant to be recycled, circularity must be built in from the start. As a company, you also have to assess your portfolio through these R-models – and we did that last year. We looked at thousands of products and asked our product owners to map them. For example, if you’re the product owner of an electrical product, it will most likely end up being recycled. With my background in mechanical engineering, I know how crucial it is to understand the design and materials used – the plastics, for instance – and to ask from the start: can it really be recycled? What design changes would be needed for it to be repaired instead?

The second part is what we call embracing circular business – introducing models like product-as-a-service or lifetime-extending agreements. Finally, we aim to empower our customers to become more circular – showing them they don’t always need to replace, but can repair instead. That’s the framework we work within at Siemens.

You were just sharing about circular business models. If someone reading this interview is wondering: would that be something for me – where would you start?

The simplest example is probably a rental model or product-as-a-service. Instead of selling your products, you rent them out. But not every product is suitable for that. People are happy to rent skis – but not ski jackets. So you have to ask yourself: do I have the right product portfolio for this? Would my customers actually want that? And if they don’t, then at least aim for the best possible recycling model. Make sure that what’s inside your products finds its way back into new ones – truly closing the loop instead of ending up as waste somewhere. That also means getting closer to your customer. Meanwhile, there are large platforms where you can buy refurbished or pre-owned electrical products – like JC Electronics, an expanding e-commerce marketplace focused on refurbished electronics. It reflects a rising consumer interest in circular business models. These players buy used products, refurbish them, and sell them again.

In fashion, we are seeing the same trend – pre-owned or “pre-loved” items are on the rise.

Yes! I recently spoke with colleagues in China, where dedicated stores for pre-owned fashion have opened in cities like Shanghai and Beijing. You can go in and enjoy a full luxury retail experience – but everything on sale is second-hand. On a macroeconomic level, trade tensions are also driving this shift. Companies increasingly need to use what’s available locally. Second-hand markets are growing because global shipping and production are becoming more complex and costly.

And what does the future of circularity look like?

At Siemens, we focus on material scarcity – especially metals that will become increasingly expensive. We must recover materials like aluminium, steel, and copper from products we’ve already produced, as our electronic components depend on them. It’s fascinating to see raw material prices rise and realise how difficult sourcing will become. The question is: can we keep these materials within our own loop? It’s challenging, especially with electrical components, but also exciting. Recyclers are becoming more advanced through robotics and AI, learning to dismantle components more efficiently. That connects directly to our work. We have a partnership with a company that melts old nylon fibres to produce our housings, while others turn used cooking oil into plastics for our components. Innovation in this field is rapid – and essential.

Can you also cut down costs by being more circular?

Definitely. When we talk about sustainability, it often adds extra costs. But with circularity, we actually see strong business potential – especially in what we call retrofitting. We visit customers who have large installations of electrical equipment that are outdated – some of them have been running for 40 years. We can then say: you don’t have to replace the entire system. You can retrofit it to modern standards. That’s where the cost savings come in. It may be better to repair than buy new. It should always be considered.

And if you’re a start-up founder reading this interview and thinking about a product launch – how can they integrate a circular business model from the very beginning?

My recommendation would be to consider from the start what will happen at the end of your product’s life. Talk to customers, try to understand what happens at the end of the life cycle – and see if you can get it back. Take a simple example, like a leather handbag: if you know you’ll buy back used handbags, that changes how you design them. You’ll make sure they last longer. So when creating a new product, think circular – don’t just sell it and forget it. Care about what happens once it’s been used.

I recently saw a very interesting Swiss watch company, ID Watch. For them, circularity is embedded into the design. They have created a watch whose plastic can be gently melted with a hairdryer to remove scratches. That’s smart thinking. Take ownership of what you produce and plan how to get it back. And once you have it back, what will you do with it? Will you resell it – which means you’ll need to fix scratches and make it look new again – or reuse the materials for something else? That’s what true product ownership means. I honestly wish more companies would think this way.

What would you recommend we do with our printed magazines?

Just share them. Pass them on – don’t throw them away. Give them to someone else to read. I think it would be wonderful if the magazine even carried that message: that it’s meant to be passed along, that it’s been touched before – because another woman has read it. The worst thing would be for it to end up in the regular rubbish bin. And, of course, make sure the paper you use can be recycled.

It is. Also, our packaging for postal delivery is recyclable. But I see what you mean by “start to think circular.”

Exactly – that’s what we mean by empowering the customer. You have to make it easy for the reader, or the user, to know what to do next. But you can always be circular – that’s the message I want to spread through you. If we were in a room with 300 women, like at your Female Innovation Forum, and let’s imagine the world suddenly ended – I’m sure we would already have enough things for the rest of our lives. We’d just share them.

It’s time for the world economy to shift

Our consumption patterns are depleting resources, increasing waste, and harming the environment. Businesses face pressure to innovate, remain competitive, and build resilience.

Siemens is helping entire industries transition from linear to circular. They create circular products, embrace circular business, and empower circularity across sectors – decoupling growth from consumption.

By scaling circularity, Siemens reduces the burden on the planet while creating opportunities for growth and innovation.

Visit: Siemens / Circularity